In line with its core value of striving for excellence, Jetta is among the few that has an independent R & D team focusing on innovation projects. The team has engaged on:

- finding solutions to challenges posed by customers to meet new requirements that prevailing manufacturing processes cannot meet with;

- developing new processes to cope with the increasing awareness in environmental and safety concerns; and

- developing innovative daily life products that provide a better solution to people’s needs.

Built on the solid experience in manufacturing, Jetta has successfully come up with a number of innovative processes and products. Some of them have been patented and become Jetta’s Intellectual Property (IP).

Jetta’s R&D team has developed a number of new processes resulting in the realization of some innovative products for its customers. Some examples are:

- Hollow doll heads made by injection molding instead of roto-casting

- Mini quiet AC motor;

- Electroforming electrodes mold making process for highly detailed ornaments;

- Goble shell printing and forming process;

- Soft skin mold making and molding process for PLEO the robotic dinosaur;

- Highly precision plastic gear tool making process with ‘point to point’ shrinkage compensation;

- 3D mapping software to generate flat plate artwork for contoured surface graphics.

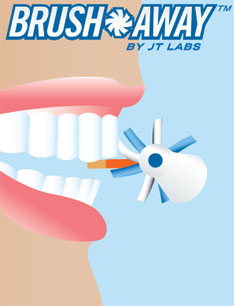

Other than developing innovative manufacturing processes, Jetta has been putting effort in creating innovative products. This is also part of the diversification effort Jetta made to move into non-toys production. These innovations aim at addressing the physical needs of people.

“How can we brush our teeth cleaner?” “How can we sleep better?” With a view to providing a better solution to our daily life activities, Jetta has been in the process to commercialize some of these innovative products:

|

|

In order to protect the results of Jetta’s innovation, some of them have been patented and some of them are patent pending.

In June 2009 Jetta acquired the IP of PLEO the robotic dinosaur. This provides a platform for Jetta not just applying its technical prowess in manufacturing but its creativity in product development and marketing. It also opens up an market opportunity to Jetta that never has before.

A little history

In mid 90s, a challenge came when the banning of using PVC in toys was under discussion. McDonald Europe decided to ban the use of PVC in its Happy Meal premium toys. Substitute materials are available for most of the PVC components but not for hollow doll head. Traditionally, hollow doll head is made in PVC by roto-casting. The challenge is to make the doll head in a non-PVC material and at the same time to mold the head without a noticeable parting line along the face. No alternatives were known at that time.

Jetta took up the challenge and successfully developed a new mold making and molding process. With the new process, hollow doll heads can be made by injection molding using TPE material. Compared with the traditional roto-casting process, the new process gives better quality and uses less labor. The new process was subsequently granted a US patent. Other than internal manufacturing, Jetta has licensed the new process to other manufacturers under royalty agreement. It is believed that the new process has great licensing potential when PVC is completely banned in doll making.

Jetta takes the view that information technology (IT) provides us with the power not only to “automate”, but also to “informate” and then to “transformate”. “Automate” means to replace the human body with a technology that enables the same processes to be performed with more continuity and control. “Informate” means IT generates information (about the underlying processes), which, when presented in a particular manner and at an appropriate time, improves the knowledge (understanding) of the person receiving it in such a way that the person is able to undertake a required action or make a required decision. “Transformate” means to redefine the scope of the business with new, information-based products and services.

Jetta takes the view that information technology (IT) provides us with the power not only to “automate”, but also to “informate” and then to “transformate”. “Automate” means to replace the human body with a technology that enables the same processes to be performed with more continuity and control. “Informate” means IT generates information (about the underlying processes), which, when presented in a particular manner and at an appropriate time, improves the knowledge (understanding) of the person receiving it in such a way that the person is able to undertake a required action or make a required decision. “Transformate” means to redefine the scope of the business with new, information-based products and services.