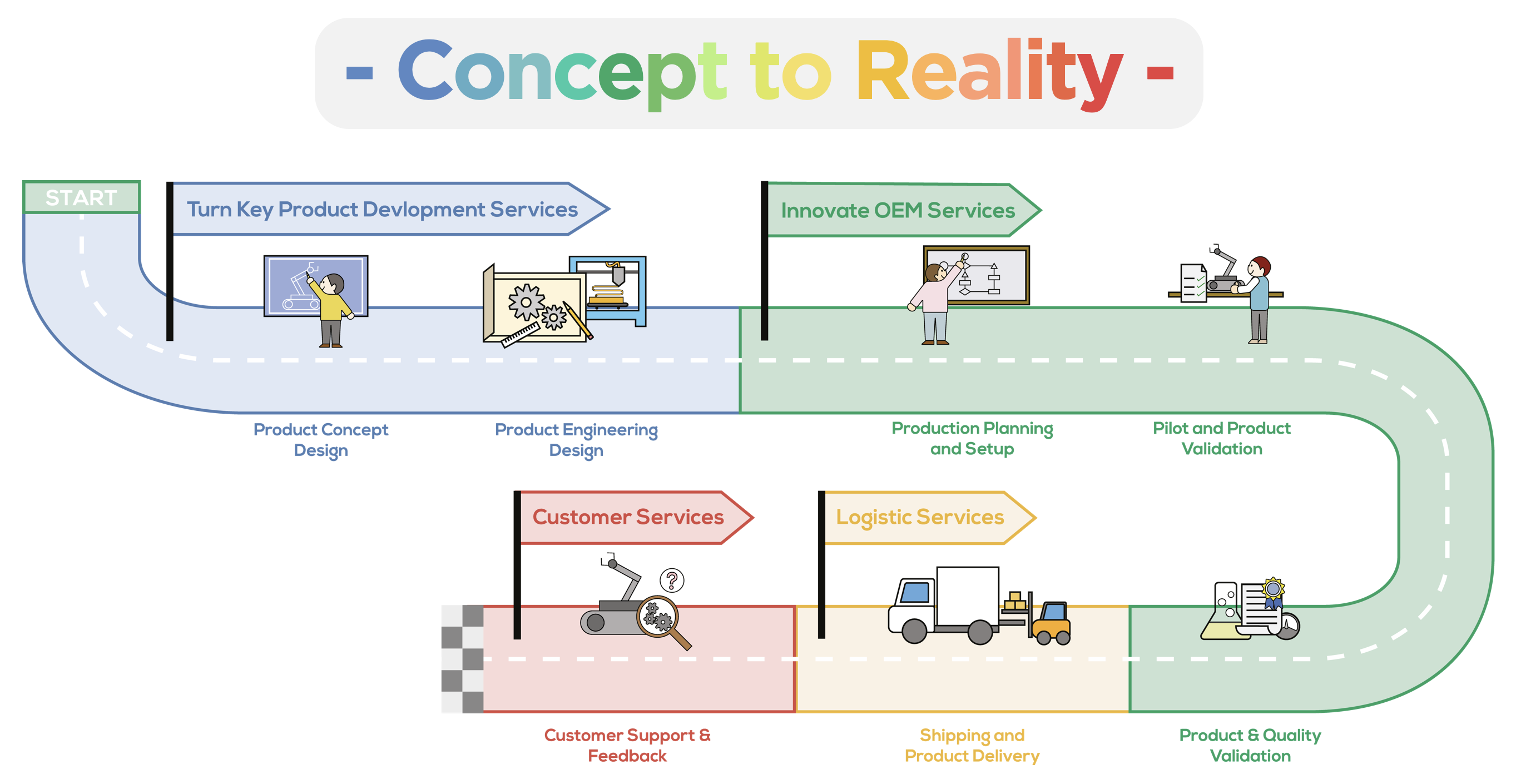

STAGE 1 - Product Concept Design

- Turn-key product development

- Realizing your product concept from conceptual stage

- Handled by talented and innovative in-house engineering/design teams

- Materialize your concept first into breadboard models or prototype designs

- Analytical and cost evaluation for production feasibility

STAGE 2 - Product Engineering Design

- Customer-focused OEM engineering development

- Assist customers with technical insights by providing opinion, advice and continuous feedback

- Design products for cost-effective volume manufacturing

- Develop detailed product design specification with latest design tools

- Generate engineering design CAD/CAM models and drawings

- In-house model making to create work-like models

- Advanced rapid-prototyping (High-speed SLS technology)

- Model testing and validation

STAGE 3 - Tooling and Engineering Pilot

- In-house tools fabrication for seamless assembly

- State-of-the-art computerized mold making technology integrated with CAD/CAM systems

- Comprehensive tools debugging support by modern test equipment

- Product safety and reliability testing (e.g. drop test)

- Product validation and sampling to optimize product quality

STAGE 4 - Production Planning and Setup

- Tight production planning and control to maximize production efficiency

- Centralized MRP/MRPII information system to keep track of material resources

- Real-time sharing of information relating to customer orders, material resources, production and shipment schedule

- Contemporary production techniques used include JIT, demand-flow technology, and statistical process control, etc.

- Manufacturing process and equipment setup optimized for quality, speed, cost effectiveness and zero-defect manufacturability

STAGE 5 - Mass Production and Quality Validation

- Piloting in production environment

- Final production testing

- High-volume manufacturing, quick turn-around and fast ramp-up production

- Flexible and scalable production capacity to meet customer’s volume demands

- Strict quality assurance and control at different stage of production

- In-coming material quality inspection (IQC) to ensure acceptable parts

- In-process quality control by closely monitoring every production processes

- Finished goods inspection to ensure products adhered to high quality standards

- Regular product auditing carried out to assure end products meet or exceed customer expectations

STAGE 6 - Logistics Service and Customer Service

- Provides vertically integrated manufacturing facilities that offer OEM customers world-class logistic support including product packaging and shipments

- Short ordering lead time and high shipment adherence

- Regular reporting on production and shipment status to customers

- Tight coordination with customers, suppliers, production, and warehouse

- Customer support and post-production service to respond to customers’ feedback and new purchase order requirements